What is BET surface area and why is it important in determining particle size?

Surface area plays a crucial role in determining the physical and chemical properties of particulate materials. The BET surface area, named after Brunauer, Emmett, and Teller, quantifies the total surface area available for interaction within a material. It is a vital parameter in analyzing particle size, as materials with smaller particle sizes usually exhibit larger surface areas due to the increased number of particles present.

The importance of BET surface area in determining particle size lies in its ability to provide a standardized method for quantifying the surface area of porous materials. By accurately measuring the surface area, researchers can better understand the reactivity, adsorption capacity, and physical behavior of particles. This information is invaluable in various fields, including chemical engineering, material sciences, and environmental studies, as it allows for precise control and optimization of particle size-dependent properties.

Understanding the principles behind the BET method of measuring surface area

The BET method, which stands for Brunauer-Emmett-Teller, is a widely used technique for determining the surface area of solid materials. This method is based on the principle that gas molecules can be adsorbed onto the surface of a solid material, forming a monolayer. By analyzing the amount of gas adsorbed at different pressures, the BET method can provide valuable information about the surface area of the material.

One key aspect of the BET method is the assumption that all molecules in the gas phase are identical and that they adsorb onto the surface in a uniform manner. This assumption allows for the calculation of a specific surface area, which is expressed in square meters per gram of material. By understanding the principles behind the BET method, researchers can accurately determine the surface area of materials, which is crucial for various applications in fields such as catalysis, material science, and environmental science.

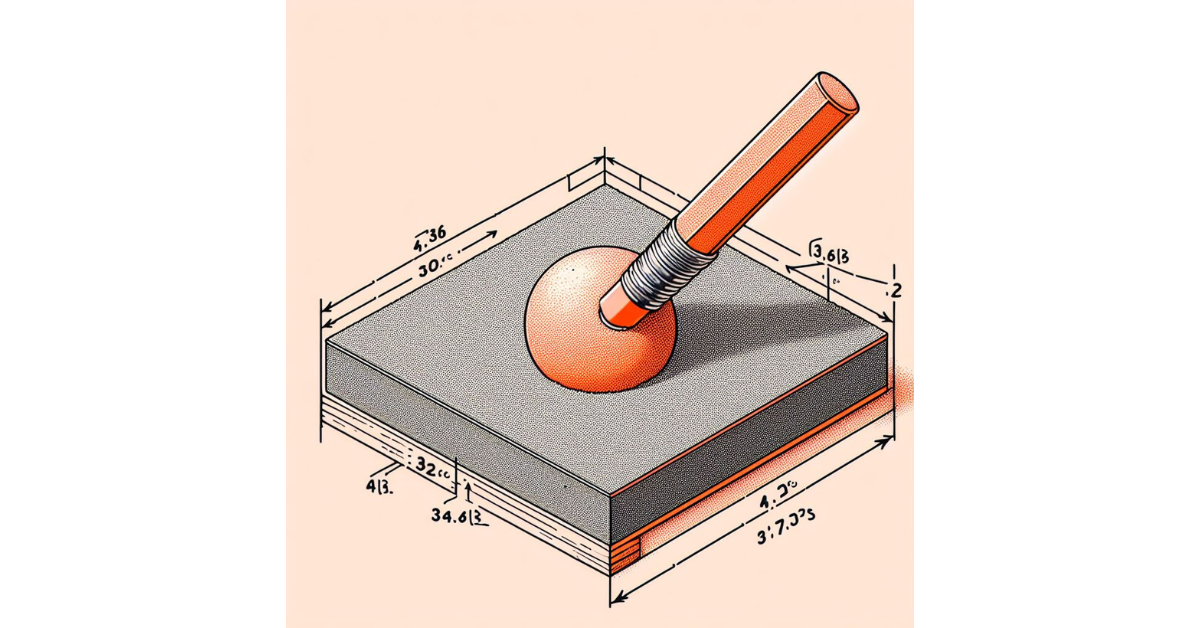

Step-by-step guide on how to calculate particle size using BET surface area

Firstly, begin by collecting the required data for the BET surface area measurement. Ensure that the sample you are analyzing is in a finely powdered form to obtain accurate results. Properly degas the sample under vacuum to remove any contaminants or adsorbed gases that may affect the surface area measurement.

Next, utilize the BET equation to calculate the surface area of the sample. Plot the nitrogen adsorption data and determine the BET constant, which is essential for the calculation. By following the step-by-step procedure outlined in the BET method, you can accurately determine the surface area, which in turn allows you to calculate the particle size of the material under analysis.

Factors to consider when using BET surface area to determine particle size

One important factor to consider when using BET surface area to determine particle size is the assumption that the particles are spherical in shape. The BET method assumes that the particles are monolayer-covered and have a uniform size and shape. Deviations from these assumptions can lead to inaccuracies in calculating the particle size, making it crucial to ensure that the particles meet these criteria before applying the BET method.

Another factor to take into account is the cleanliness and uniformity of the sample surface. Any contaminants or irregularities on the surface can skew the results obtained from the BET analysis, affecting the accuracy of the calculated particle size. It is essential to properly clean and prepare the sample to ensure that the surface is free of any impurities or inconsistencies that could impact the BET surface area measurement and subsequent particle size determination.

Common mistakes to avoid when calculating particle size from BET surface area

One common mistake when calculating particle size from BET surface area is neglecting to properly account for the assumptions and limitations of the method. The BET method assumes that all pores are monolayer accessible and that the surface is infinitely smooth, which may not always be accurate for every type of material. Failing to consider these assumptions can lead to inaccuracies in the calculated particle size.

Another mistake to avoid is using incorrect or outdated software for data analysis. It is important to use the most up-to-date software that is specifically designed for BET surface area calculations to ensure accurate results. Using outdated software may not have the necessary algorithms or features to account for complex surface characteristics, resulting in erroneous particle size calculations.